Brescia Hook pt. 3

It is called POM, short for Polyoxymethylene, and it is one of the most interesting engineering plastics developed for industrial use.

This material has highly valuable properties: it resists light, heat, and cold extremely well, maintaining its stable structure even when subjected to significant temperature changes.

Another key aspect of POM is its high elastic modulus. But what does that actually mean?

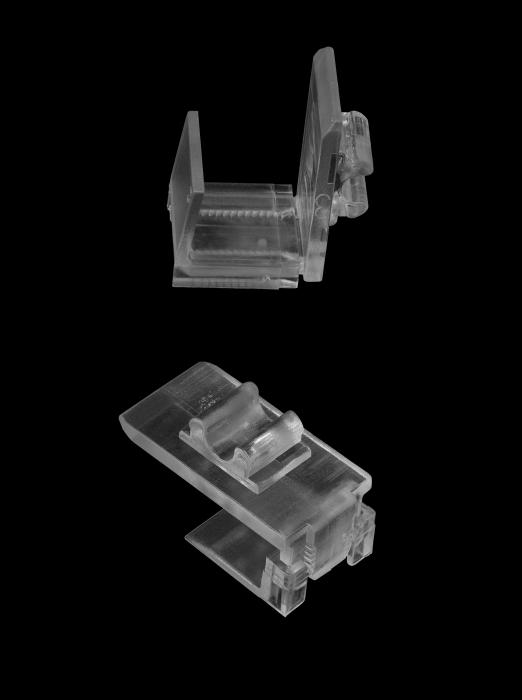

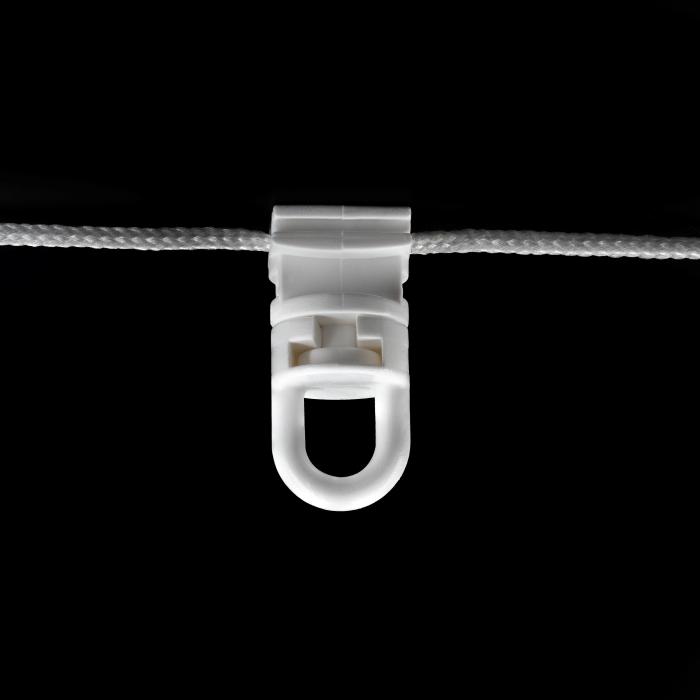

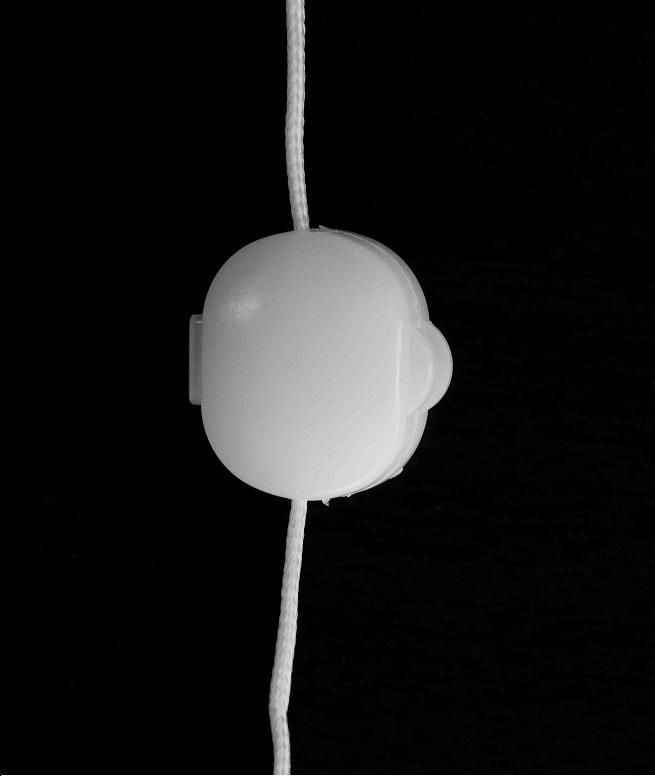

It means that when the material is forced or opened to allow the insertion of two component such as a curtain glider and the curtain tape it returns to its original shape once the stress is removed.

This ability to recover makes it ideal for systems that require frequent assembly or repeated movement, without the risk of sudden breakage.

Industrial plastics were introduced only at the end of the 1960s. POM is a copolymer, and copolymers differ from earlier homopolymers because they are more malleable and flexible.

Homopolymers, although they may appear more rigid and resistant, reach a stress point beyond which they tend to break suddenly.

A copolymer, instead, ensures flexibility, malleability, and resilience, allowing the material to deform and then return to its original form without structural damage.

Puntata Precendente: Brescia Hook pt. 2